Top Guar Gum Industrial Uses: Essential Applications and Benefits

Guar gum is a natural polysaccharide derived from the seeds of the Cyamopsis tetragonoloba plant, commonly known as the guar plant. It is native to arid regions of India and Pakistan. This drought resistant legume has gained global recognition for its industrial uses.

Guar gum is a thickening agent, stabilizer and emulsifier in diverse industries. It is extensively used in food, pharmaceutical, textile and oil and gas sectors. Derived from the endosperm of the guar or cluster bean plant, guar gum contains galactomannan, a complex carbohydrate composed of galactose and mannose sugars.

Composition and Molecular Structure

The guar seed comprises three main components: the outer husk, the germ and the endosperm. The segment of this plant that is significant in various industry applications is the endosperm, which contains high galactomannan levels. This makes guar gum highly soluble in water and capable of forming viscous solutions even at low concentrations.

Hydroxyl groups present in the guar gum molecule facilitate hydrogen bonding, which is central to its thickening and stabilizing properties. It is highly effective in altering the viscosity and stability of solutions due to its molecular structure, which enables it to form a strong hydrogen bond with water.

Physico-Chemical Properties

Guar gum is characterized by its ability to swell and dissolve in polar solvents such as water. This helps in the formation of viscous solutions. These solutions exhibit pseudoplastic (shear-thinning) behavior which is essential for flow control in industrial processes.

- Solubility and Swelling: Better with finer particle size and higher temperature.

- pH Stability: Stable over a wide pH range, though hydration rates may vary.

- Viscosity Control: Allows for precise modulation in product formulations.

These properties make guar gum an indispensable additive in processes requiring rheological modification.

Key Industrial Applications

1. Food Industry

Guar gum in food industry is widely used. It is valued in this sector for its thickening, stabilizing and emulsifying properties. The capability of guar gum benefits many food products. It is used in:

- Dairy Products for stabilizing texture in ice cream, yogurt and cheese.

- Baked Goods for increasing moisture retention, better texture and shelf life.

- Gluten-Free Products for binding ingredients in the absence of gluten.

- Soups and Sauces for improving mouthfeel and consistency.

Being 100% natural, gluten free and vegan, guar gum is a clean-label additive that appeals to health-conscious consumers.

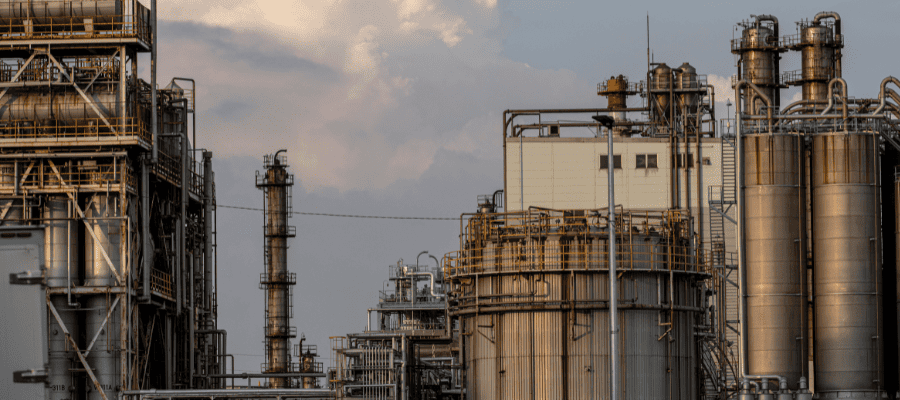

2. Oil and Gas Industry

Guar gum is significant in petroleum exploration and production, especially in hydraulic fracturing (fracking) and enhanced oil recovery (EOR). It is used in:

- Fracturing Fluids as a gelling agent to transport proppants.

- Corrosion Inhibitor as a biodegradable, green alternative to synthetic chemicals.

- Drilling Muds and Emulsion Breakers to stabilize boreholes and separate oil water mixtures.

Guar gum’s high viscosity and shear-thinning behavior make it ideal for extreme downhole conditions.

3. Pharmaceutical Industry

Guar gum is used in:

- Controlled drug release systems due to its gel-forming capability.

- Laxatives and fiber supplements to help regulate bowel movements.

- Prebiotic formulations for supporting gut flora health.

Guar gum’s natural origin and non-toxic profile make it suitable for both nutraceuticals and medical applications.

4. Textile and Paper Industries

In textiles, guar gum serves as a thickener in printing pastes and a sizing agent to strengthen yarn. In the paper industry, it improves:

- Sheet formation

- Ink absorption

- Retention of fine particles and fillers

This enhances both the visual appeal and structural integrity of the final paper products.

Guar Gum Derivatives

Chemical modifications to guar gum lead to its better performance and tailor it for specialized uses such as:

- Carboxymethyl Guar Gum: Improved solubility in cold water; used in personal care and EOR.

- Hydroxypropyl Guar Gum: Better stability in extreme pH; used in cosmetics and lubricants.

- Cationic Guar: Provides conditioning in shampoos and textile softeners.

These derivatives expand guar gum’s usability across industries requiring unique solubility, charge, or functional properties.

Biological Properties and Health Benefits

Guar gum is fermentable by Clostridium butyricum in the large intestine giving it prebiotic properties that support digestive health. Studies suggest it may aid in managing:

- Type 2 diabetes by moderating glucose absorption

- Obesity and cholesterol through increased satiety and reduced lipid absorption

- Constipation and IBS, owing to its fiber content

Its GRAS (Generally Recognized As Safe) status means it’s safe to consume.

Environmental and Economic Benefits

Guar gum is:

- Biodegradable and non-toxic, no harm to the environment.

- Cost effective, provides better viscosity at lower doses than synthetic alternatives.

- Sustainable and renewable, it comes from a hardy crop that grows in semi arid regions.

Due to this, guar gum is the responsible choice for eco conscious industries.

Future Prospects and Innovations

With increasing demand for natural, sustainable, and functional polymers, research into guar gum is expanding:

- New Derivatives: Enhancing thermal stability, salt resistance, and emulsification.

- Bioplastics and Nanogels: Exploring guar based materials for eco-friendly packaging and drug delivery.

- Synthetic Polymer Replacement: Testing guar gum as a replacement for petroleum based thickeners in cosmetics and paints.

Guar gum is at the intersection of biotechnology, sustainability and industrial innovation.

Conclusion

Guar gum is more than just a thickening agent – it’s a multi functional biopolymer driving innovation across many industries. From food textures to oil extraction and gut health, its applications are vast and growing. As industries look for greener, more sustainable materials, guar gum is emerging as a versatile, eco friendly and cost effective solution.